Resin Rich Glass Mica Tape

Product Details:

- Oil Absorption 0.5%

- Melting Point 1250C and 1500C

- CaO Content (%) 90% min

- Types of Mica Insulator

- Shape Powder

- Application Insulator

- Click to View more

X

Resin Rich Glass Mica Tape Price And Quantity

- 25 Kilograms

Resin Rich Glass Mica Tape Product Specifications

- 1250C and 1500C

- 90% min

- Insulator

- 0.5%

- Powder

- Insulator

Resin Rich Glass Mica Tape Trade Information

- 1000 Kilograms Per Day

- 7-14 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Corrugated box

- All India

Product Description

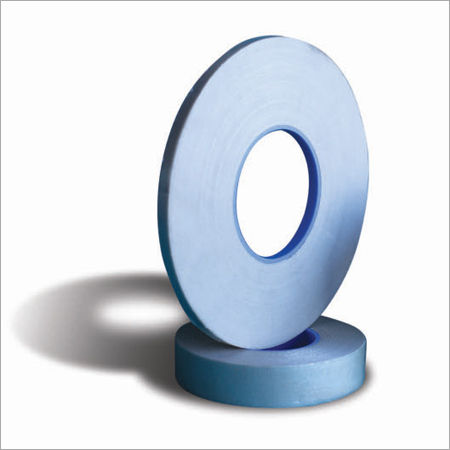

Resin Rich Glass Mica Tape

Ruby Mica Glass / Mica Resin-Rich Tape is a lamination of uncalcined muscovite mica paper with glass cloth. A thermo setting tri-functional epoxy novolac resin is used as a bonding agent making it a Class F insulation product. The tape is tack-free in cold conditions. An LDPE film interleaving is used to prevent the tape interlayers from sticking to each other during ambient temperature fluctuations.

Our resin-rich mica tapes make the coils electrically-stronger, and gives superior coil-heat dissipation capabilities.

The homogeneous insulation produced after pressing and curing has a temperature-index of at least 155.

Application

Main slot wall insulation of bars / coils in HT motors and turbo-generators. Its molded rigid laminate form can also be used to insulate commutators and form electro-thermal sleeve insulation for various applications.

Availability

- Tape roll / Folium /Wrapper

- Length : 25 - 500 m

- Width : 20 -1000 mm

Packing

- Tapes are packed in airtight robust boxes protecting them from dirt, dust and moisture.

- The packaging also ensures safe transit and storage.

Storage

- 6 months at 20C

- 12 months at 5C

Product Data

| Properties | Test Method | Unit | Value | Value | Value | Value | Value |

| Nominal Thickness | IEC 60371-2 | mm | 0.120.01 | 0.180.02 | 0.200.02 | 0.240 .02 | 0.280.02 |

| Total Substance | IEC 60371-2 | g/m2 | 16515 | 26525 | 31025 | 35025 | 46035 |

| Mica Paper | IEC 60371-2 | g/m2 | 755 | 1209 | 15010 | 18012 | 25018 |

| Glass Content | IEC 60371-2 | g/m2 | 233 | 323 | 323 | 323 | 323 |

| Resin Content | IEC 60371-2 | g/m2% | 6510 40 | 11010 40 | 12515 40 | 14015 40 | 18520 40 |

| Tensile Strength | IEC 60371-2 | N/cm |

75 | 150 | 150 | 150 | 150 |

| Resin Flow | IEC 60371-2 | 90C 160C | 20-60 40-70 | 20-60 40-70 | 20-60 40-70 | 20-60 40-70 | 20-60 40-70 |

| Volatile Contents | IEC 60371-2 | % | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-1.0 |

| Break Down Voltage(Cured laminated of 1 mm) | IEC 60243-1 | KV/mm | >40 | >40 | >40 | >40 | >40 |

Premium Insulation Solution

Designed for efficiency and reliability, Resin Rich Glass Mica Tape excels in insulation tasks for motors and turbo generators. Its superior heat resistance and low oil absorption make it ideal for high-stress environments, safeguarding equipment performance and longevity.

Versatile Applications

With its advanced specs and quality assurance, this tape caters to a wide range of uses in the electrical industry. Commonly utilized by manufacturers, suppliers, and exporters across India, it meets international standards for industrial insulation needs.

FAQs of Resin Rich Glass Mica Tape:

Q: How is Resin Rich Glass Mica Tape applied in electrical insulation systems?

A: Resin Rich Glass Mica Tape is typically wrapped or layered onto motor coils and turbo generator windings to provide robust electrical insulation, protecting against heat, moisture, and electrical discharge.Q: What benefits does a high CaO content (minimum 90%) offer for mica tapes?

A: The elevated CaO content enhances thermal stability and insulation properties, enabling the tape to withstand high operating temperatures and maintain performance under rigorous conditions.Q: When should Resin Rich Glass Mica Tape be replaced or checked for integrity?

A: It is advisable to inspect and potentially replace the tape during routine maintenance or if signs of wear, degradation, or reduced insulation performance are detected, especially within its 6 to 12 month shelf life.Q: Where is Resin Rich Glass Mica Tape most commonly used?

A: This tape is widely used in electrical manufacturing and repair facilities, primarily for insulating motors and turbo generators in industrial settings throughout India and for export markets.Q: What is the process for manufacturing Resin Rich Glass Mica Tape?

A: The tape is produced by impregnating fine mica powder with resin, layering it with glass for structural support, and then cutting or winding into precise lengths for easy application.Q: How does the low oil absorption benefit the longevity of the tape?

A: Low oil absorption (0.5%) minimizes the risk of contaminant ingress, preserving the insulations integrity and extending the operational life of equipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese