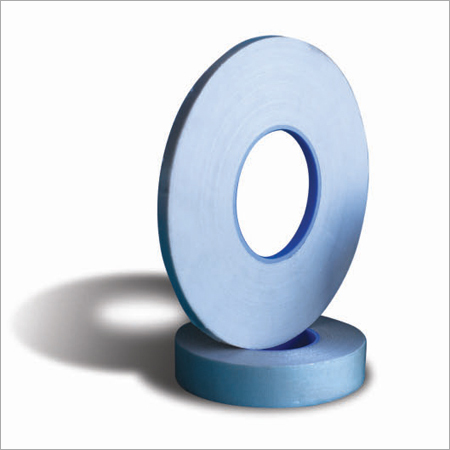

Glass Mica Tape

Product Details:

- Melting Point 1250C and 1500C

- CaO Content (%) 90% min

- Oil Absorption 0.5%

- Types of Mica Insulator

- Shape Powder

- Application Insulator

- Click to View more

X

Glass Mica Tape Price And Quantity

- 25 Kilograms

Glass Mica Tape Product Specifications

- 1250C and 1500C

- Powder

- Insulator

- Insulator

- 90% min

- 0.5%

Glass Mica Tape Trade Information

- 1000 Kilograms Per Day

- 7-14 Days

- Yes

- Free samples are available

- Corrugated box

- All India

Product Description

Glass or Mica Tape

Ruby Mica Glass Mica Tape is a lamination of uncalcined muscovite / phlogopite mica paper with glass cloth. High thermal-grade silicone resin is used as a bonding agent making it a Class H insulation product. Highly-porous mica paper is selected which has excellent resin absorbing properties. The GM Tape's good flexibility with minimal thickness contributes to the ease in conductor taping.

An additional layer of glass cloth may also be laminated on top of mica paper. This GMG Tape has an increased thermal conductivity for better coil-heat dissipation and nearly doubles the tensile-strength of GM tape.

Application

Inter-turn conductor insulation suitable for resin-poorVPI insulation system of HT motors and generators, Class H insulation in transformers, induction furnace coil insulation etc.

Availability

- Tape roll / Folium /Wrapper

- Length : 25 - 500 m

- Width : 6 - 1000 mm

Packing

Tapes are packed in airtight robust boxes protecting them from dirt, dust and moisture. The packaging also ensures safe transit and storage.

Storage

6 months at 20C - 12 months at 5C

Product Data

| Properties | Test Method | Unit | Value | Value | Value | Value | Value |

| Nominal Thickness | IEC 60371-2 | mm | 0.10.01 | 0.130.01 | 0.150.01 | 0.180 .02 | 0.20.02 |

| Total Substance | IEC 60371-2 | g/m2 | 13010 | 16515 | 19515 | 23520 | 26020 |

| Mica Paper | IEC 60371-2 | g/m2 | 805 | 1209 | 15010 | 18012 | 20015 |

| Glass Content | IEC 60371-2 | g/m2 | 233 | 323 | 323 | 323 | 323 |

| Resin Content | IEC 60371-2 | g/m2% | 153 12-15 | 203 12-15 | 253 12-15 | 303 12-15 | 353 12-15 |

| Tensile Strength | IEC 60371-2 | N/cm | 75 | 120 | 120 | 120 | 120 |

| Volatile Strength | IEC 60371-2 | % | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Break Down Voltage | IEC 60243-1 | KV/mm | 15 | 15 | 15 | 15 | 15 |

Exceptional Insulation for Industrial Applications

Our Glass Mica Tape is specifically crafted to meet the high demands of electrical insulation in motors and generators. With its high CaO content and resilient mica composition, it ensures dependable performance in challenging environments. Its versatility in tape length and thickness allows for customized solutions in your insulation processes.

Durability and High-Temperature Resistance

Designed to endure extreme heat, this tape remains stable at melting points up to 1500C. Its low oil absorption guarantees sustained effectiveness, making it an ideal choice for industries requiring unfailing insulation under strenuous operational conditions. The white color offers easy identification during installation.

FAQs of Glass Mica Tape:

Q: How is Glass Mica Tape used in motors and generators?

A: Glass Mica Tape acts as an insulation layer in motors and generators, safeguarding internal components from electrical faults and enhancing operational safety. It is wrapped or layered around wires and coils, ensuring robust and long-lasting insulation.Q: What benefits does the high CaO content provide in Glass Mica Tape?

A: The high CaO content (90% minimum) improves the thermal stability and dielectric strength of the tape, ensuring reliable insulation in high-voltage environments such as motors and generators.Q: When should you replace Glass Mica Tape considering its shelf life?

A: Given that the shelf life is 6 months, it is recommended to replace or use the tape within this period to maintain optimal insulation properties and safety in electrical applications.Q: Where is this Glass Mica Tape manufactured and supplied from?

A: This tape is manufactured, exported, and supplied directly from India, offering high-quality products to local and international markets for industrial insulation needs.Q: What is the process of applying Glass Mica Tape?

A: The tape is applied by wrapping or layering it onto coils or wires in motors or generators. Its flexibility and varying length allow for precise fitting and secure insulation during manufacturing or maintenance.Q: What makes this tape suitable for high-temperature environments?

A: With melting points between 1250C and 1500C, the tape resists thermal degradation, making it ideal for use in motors, generators, and other equipment subject to extreme temperatures.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese