Epoxy Bonded Resin Mica Tape

Product Details:

- Oil Absorption 0.5%

- Melting Point 1250C and 1500C

- CaO Content (%) 90% min

- Types of Mica Insulator

- Shape Powder

- Application Insulator

- Click to View more

X

Epoxy Bonded Resin Mica Tape Price And Quantity

- 25 , , Kilograms

Epoxy Bonded Resin Mica Tape Product Specifications

- Insulator

- 0.5%

- 1250C and 1500C

- 90% min

- Insulator

- Powder

Epoxy Bonded Resin Mica Tape Trade Information

- 1000 , , Kilograms Per Day

- 7-14 Days

- Yes

- Free samples are available

- Corrugated box

- All India

Product Description

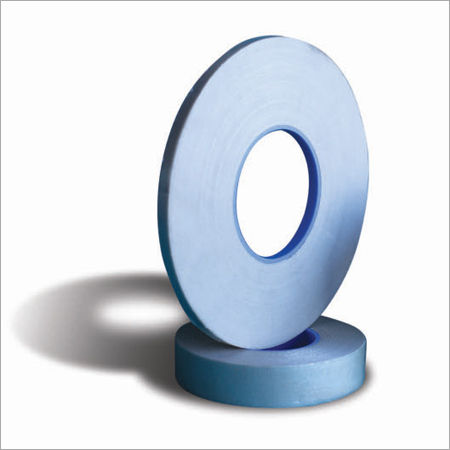

Having advanced manufacturing unit, we are able to manufacture, export and supply superior quality Epoxy Bonded Resin Mica Tape. Offered tape is extensively used for insulating the conductor coils in motors and generators. Our adroit professionals use quality approved mica and advanced techniques to process this tape. Moreover, our clients can easily avail this Epoxy Bonded Resin Poor VPI Glass Mica Tape from us at reasonable prices.

Features:

-

Resistant to abrasion

-

High thermal stability

-

Chemically inert

-

Highly flexible

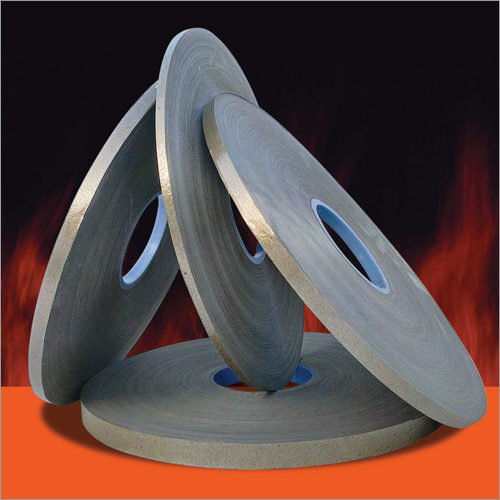

Epoxy Bonded Resin Poor VPI Glass Mica Tape

Product Data

| Properties | Test Method | Unit | Value | Value |

| Nominal Thickness | IEC 60371 - 2 | mm | 0.10.01 | 0.120.01 |

| Total susbstance | IEC 60371 - 2 | g/m2 | 11810 | 16415 |

| Mica Paper | IEC 60371 - 2 | g/m2 | 705 | 1138 |

| Glass Content | IEC 60371 - 2 | g/m2 | 332 | 332 |

| Aramid* Fibroids | IEC 60371 - 2 | g/m2 | 52 | 73 |

| Resin Content | IEC 60371 - 2 | g/m2 | 102 | 123 |

| Tensile Strength | IEC 60371 - 2 | N/cm | 150 | 150 |

| Air Porosity | IEC 60371 - 2 | S/100ml | >1600 | >2500 |

| Volatile Contents | IEC 60371 - 2 | % | 0.5 | 0.5 |

High-Performance Insulation for Demanding Applications

Epoxy Bonded Resin Mica Tape stands out for its exceptional electrical and thermal insulation properties, making it a preferred choice in motor and generator manufacturing. Its powder-shaped mica core and robust resin bonding provide durability and minimal oil absorption, ensuring optimal performance in challenging environments. Offered in multiple colors and sizes, the tape meets varied industrial needs while maintaining its integrity and shelf life for up to 12 months.

Engineered for Reliability and Safety

With its high melting point and low oil absorption, this mica tape offers superior safety for electrical insulation. Composed of insulator-grade mica and featuring at least 90% CaO content, it resists degradation under heat and stress. Its adaptable size range makes it easy to install, supporting stability and safety in electrical assemblies for both domestic and exported equipment.

FAQs of Epoxy Bonded Resin Mica Tape:

Q: How should Epoxy Bonded Resin Mica Tape be used in motors and generators?

A: Epoxy Bonded Resin Mica Tape is applied as a protective layer on coils and windings of motors and generators to provide insulation against high voltage and temperature. It should be wound or layered according to your machines requirements and then cured as per industry standards for best performance.Q: What are the available color options for this mica tape?

A: This resin mica tape is available in white, grey, and brown, allowing for easy differentiation and color-coding in industrial applications.Q: When can I expect the shelf life of this tape to expire?

A: The tape maintains optimal properties for 6 to 12 months when stored under recommended conditions, so its best to use the product within this period for maximum effectiveness.Q: Where is this mica tape manufactured and exported from?

A: This product is manufactured, supplied, and exported from India, serving industries both domestically and internationally.Q: What is the manufacturing process of Epoxy Bonded Resin Mica Tape?

A: The process involves bonding insulator-grade mica powder with a specialized resin, forming a tape that combines the excellent insulating properties of mica with the strength and flexibility of resin. The tape is precisely cut to required widths and lengths.Q: What are the main benefits of using this tape in electrical equipment?

A: The tape offers outstanding electrical insulation, heat resistance (melting point up to 1500C), low oil absorption, and durability, making it highly reliable for demanding electrical applications such as motors and generators.Q: Is this tape suitable for high-temperature applications?

A: Yes, the tape is engineered to withstand high temperatures, with a melting point ranging from 1250C to 1500C, ensuring safe and durable insulation even in extreme conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese