Silicone Bonded Resin Mica Tape

Product Details:

- CaO Content (%) 90% min

- Melting Point 1250C and 1500C

- Oil Absorption 0.5%

- Types of Mica Insulator

- Shape Powder

- Application Insulator

- Click to View more

X

Silicone Bonded Resin Mica Tape Price And Quantity

- 25 Kilograms

Silicone Bonded Resin Mica Tape Product Specifications

- Insulator

- 0.5%

- Insulator

- 1250C and 1500C

- 90% min

- Powder

Silicone Bonded Resin Mica Tape Trade Information

- 1000 Kilograms Per Day

- 7-14 Days

- Yes

- Free samples are available

- Corrugated box

- All India

Product Description

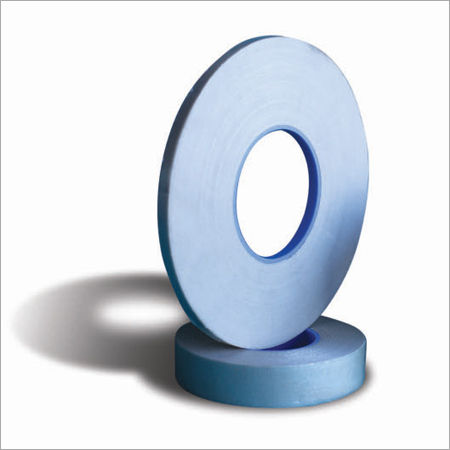

Silicone Bonded Resin Poor VPI Glass Mica Tape

Ruby Mica Glass / Mica Silicone VPI Tape is a lamination of calcined muscovite mica paper with glass cloth. High thermal-grade silicone resin is used as a bonding agent making it a Class H insulation product. Mica paper is infused with Aramid* Fibroids to strengthen and enhance its resin-absorption capabilities making it suitable for vacuum pressure impregnation (VPI). Post-curing temperature-index is 200C.

A choice of uncalcined highly porous muscovite mica paper with Class F epoxy resin as a binding agent is also available. This Glass / Mica Epoxy VPI Tape contains zinc napthenate as an accelerator.

Application

Main slot wall insulation of conductor coils and bars in HT motors and generators. It is suitable for both hand and machine-taping on coils / bars of high-voltage rotating-machines. Its outstanding resin-penetration properties make it ideal for single vacuum pressure impregnation of fully-wound stator coils.

Availability

- Tape roll

- Length 25 - 200 m

- Width 10-30 mm

Packing

Tapes are packed in airtight robust boxes protecting them from dirt, dust and moisture. The packaging also ensures safe transit and storage.

Storage

12 months at 25C - 24 months at 5C

Exceptional Electrical Insulation

Silicone Bonded Resin Mica Tape delivers robust dielectric protection, making it an ideal insulator for high-voltage applications such as coils, bars, motors, and generators. Its engineered resilience maintains insulation integrity even under demanding thermal and mechanical conditions.

Superior Thermal Resistance

Withstanding temperatures up to 1500C, our mica tape is purpose-built for environments where traditional insulators would degrade. This superior heat resistance ensures the longevity and safety of electrical components in industrial settings.

Versatility in Application

The tapes flexible dimensions and extended shelf life make it suitable for various industrial applications. Its ability to resist oil absorption and provide reliable performance over time is highly valued by manufacturers and maintenance professionals worldwide.

FAQs of Silicone Bonded Resin Mica Tape:

Q: How is Silicone Bonded Resin Mica Tape applied in industrial settings?

A: This tape is wrapped around coils, bars, motors, and generators to ensure reliable insulation. It can be used in automated or manual taping processes, providing uniform coverage and robust protection against heat and electrical stress.Q: What advantages does the tapes high melting point provide?

A: The melting point of 1250C to 1500C allows the tape to function effectively in high-temperature operations, preventing insulation failure and extending the life of electrical equipment.Q: Where can this mica tape be used most effectively?

A: It is especially effective in power generation, transformer manufacturing, motor production, and environments requiring superior electrical and thermal insulation. Its widely used by OEMs and maintenance professionals in India and exported globally.Q: What is the recommended shelf life, and how should the tape be stored?

A: With a shelf life of 12 to 24 months, the tape should be kept in a cool, dry place away from direct sunlight and moisture to maintain its insulating properties.Q: How does the tapes oil absorption capacity impact its performance?

A: A low oil absorption rate of 0.5% ensures the tape maintains its insulating capability, even in oily or humid conditions, reducing risk of dielectric breakdown and equipment malfunction.Q: What process is involved in manufacturing this mica tape?

A: The tape is created by bonding mica powder with a silicone resin, producing flexible strips that can be tailored to specific widths and lengths for easy application and optimal fit in various installations.Q: What are the key benefits of using Indian-manufactured Silicone Bonded Resin Mica Tape?

A: Indian manufacturing ensures adherence to international quality standards, competitive pricing, reliable supply chains, and bespoke solutions for OEMs and industrial clients worldwide.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese