Kapton Mica Tape

Product Details:

- Melting Point 1250C and 1500C

- Oil Absorption 0.5%

- CaO Content (%) 90% min

- Types of Mica Insulator

- Shape Powder

- Application Insulator

- Click to View more

X

Kapton Mica Tape Price And Quantity

- 25 Kilograms

Kapton Mica Tape Product Specifications

- 1250C and 1500C

- 0.5%

- Powder

- 90% min

- Insulator

- Insulator

Kapton Mica Tape Trade Information

- 1000 Kilograms Per Day

- 7-14 Days

- Yes

- Free samples are available

- Corrugated box

- All India

Product Description

Kapton Mica Tape

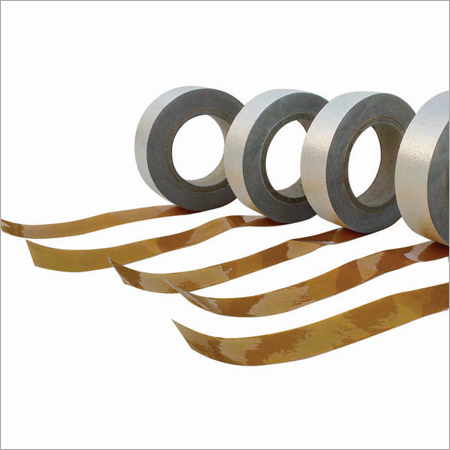

Ruby Mica Uniform Kapton I Mica Tape is a lamination of calcined muscovite mica paper with a Kapton Polyimide Film. Mica paper is further reinforced with Aramid Fibroids, to aid an evenly spread, high thermal-grade silicone resin impregnation.

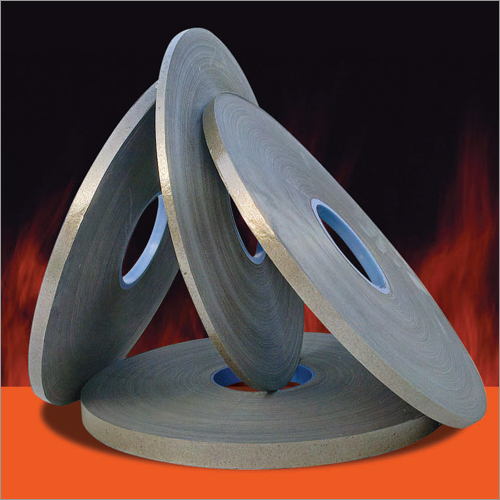

This mica tape being drastically thin spares more room for the conductor, thus helping in size-reduction of the HT motor. It almost sketches the perfect coil-insulation; surpassing the best of all insulation attributes. They have a very high partial-discharge resistance along with increased thermal-conductivity, enabling the HT motor to run cooler for longer.

Application

This uniform mica tape is used for insulation of armature coil in Class-200 traction motors.

Availability

- Tape Roll

- Length : 30 m

- Width : 25 mm

- Thickness : 0.10 mm

Packing

Tapes are packed in airtight robust boxes protecting them from dirt, dust and moisture. The packaging also ensures safe transit and storage.

Storage

12 months at 25C

Product Data

| Properties | Test Method | Unit | Value |

| Total Substance | IEC 60371 - 2 | g/m2 | 12015 |

| Mica Content | IEC 60371 - 2 | % | 564 |

| Resin Content | IEC 60371 - 2 | % | 103 |

| Aramid Fibroids | IEC 60371 - 2 | % | 41 |

| Accelerator Content | IEC 60371 - 2 | g/m2 | 2.5 |

| Tensile Strength | IEC 60371 - 2 | N/15mm | 60 |

| Breakdown Voltage | IEC 60243 - 1 | kV(Avg.) | 5.5 |

|

| IEC 60243 - 1 | kV(Min.) | 4.5 |

| Winding Property | - | - | Good |

Exceptional Insulation and Heat Resistance

Kapton Mica Tape offers optimal insulation with a high melting point, making it ideal for electrical applications such as armature coils. The combination of mica and Kapton film provides robust electrical and thermal endurance, ensuring reliable performance in high-stress environments.

Versatile Sizing for Varied Requirements

With tape widths ranging from 25 mm to 1000 mm and customizable lengths up to 500 meters, Kapton Mica Tape caters to diverse industrial needs. Its flexible dimensions allow for tailored application in electrical manufacturing, repair, and maintenance.

FAQs of Kapton Mica Tape:

Q: How is Kapton Mica Tape typically used in industrial applications?

A: Kapton Mica Tape is primarily used as an insulating material in armature coils and other electrical components requiring superior thermal and dielectric protection. Its heat resistance and excellent insulation properties make it a preferred choice for motors, transformers, and generators.Q: What are the main benefits of using Kapton Mica Tape?

A: The main benefits include exceptional electrical insulation, high thermal stability with a melting point up to 1500C, low oil absorption, and resistance to wear and aging. These features enhance the longevity and reliability of electrical equipment.Q: When should Kapton Mica Tape be replaced or checked for quality?

A: It should be stored and used within its 12-month shelf life for optimal performance. Regular inspection for wear or damage during maintenance cycles is recommended to ensure continued insulation effectiveness.Q: Where is Kapton Mica Tape manufactured and supplied from?

A: Kapton Mica Tape is manufactured, supplied, and exported from India, supporting a wide range of industrial clients both domestically and internationally.Q: What is the process for applying Kapton Mica Tape in armature coils?

A: The tape is typically wrapped or layered around the coils as an insulation barrier. Due to its flexible form and varied size options, it can be easily applied to intricate or large components during assembly or refurbishment.Q: How does the oil absorption rate affect the tapes performance?

A: With an oil absorption rate of just 0.5%, Kapton Mica Tape resists the infiltration of oils and contaminants, maintaining its dielectric properties and integrity over prolonged use in challenging industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese