Polyimide Film Tape

Product Details:

- Melting Point 1250C and 1500C

- CaO Content (%) 90% min

- Oil Absorption 0.5%

- Types of Mica Insulator

- Shape Powder

- Application Insulator

- Click to View more

X

Polyimide Film Tape Price And Quantity

- 25 Kilograms

Polyimide Film Tape Product Specifications

- 90% min

- Insulator

- 0.5%

- 1250C and 1500C

- Powder

- Insulator

Polyimide Film Tape Trade Information

- 1000 Kilograms Per Day

- 7-14 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Corrugated box

- All India

Product Description

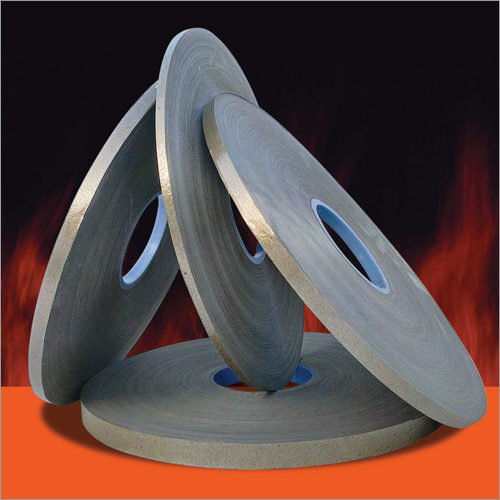

Polyimide Film Tape

Ruby Mica Polyimide Film Tape is a Kapton film-based tape that imparts excellent dielectric and thermal-stability to the conductor-strands that ensures along and efficient service-life. A thin layer of Kapton film consumes minimal space while providing robust insulation.

Application

Bare conductor strand insulation of coils, as slot liners and ground-insulation in HT motors & generators.

Availability

Polyimide tapes can be slit to desired widths and lengths. A choice of self-adhesive and non-adhesive version of the product is available.

Tape roll / Folium /Wrapper

- Length : 50 - 500 m

- Width : 6 -1000 mm

- Thickness : 25 microns

Packing

Tapes are packed in airtight robust boxes protecting them from dirt, dust and moisture. The packaging also ensures safe transit and storage.

Storage

Self-adhesive type: 12 months at 20 C - Non-adhesive type: Unlimited at 25 C

Product Data: Film Type: 100 H

| Properties | Unit | Test Value |

| Tensile Strength MD | MPa | 332 |

| Tensile Strength TD | MPa | 333 |

| Tensile Elongation MD | % | 80 |

| Tensile Elongation TD | % | 83 |

| L-color | - | 47 |

| Dielectric Strength | KV/mm | 385 |

Exceptional Thermal and Chemical Resistance

Polyimide Film Tape stands out for its superior resistance to extreme temperatures, with a melting point up to 1500C. Its robust material ensures durability in challenging environments, making it ideal for industrial insulation, electronic assemblies, and PCB manufacturing. The tapes low oil absorption and high CaO content underline its reliability for demanding tasks.

Versatile Applications Across Industries

This film tape can be used for a wide range of applications including insulator wrapping, masking during soldering, and as a protective layer in sensitive electronic settings. Its flexibility in length and consistent 25-micron thickness allow for tailored use in various manufacturing and maintenance scenarios.

FAQs of Polyimide Film Tape:

Q: How is Polyimide Film Tape typically used in industrial settings?

A: Polyimide Film Tape is commonly used for insulation purposes, including wrapping wires and cables, masking in electronic manufacturing, and as a protective barrier during high-temperature processing.Q: What are the benefits of using Polyimide Film Tape with a 25-micron thickness?

A: A 25-micron thickness provides an optimal balance between flexibility and strength, ensuring effective insulation without adding bulk or compromising ease of application.Q: When should Polyimide Film Tape be replaced or reapplied?

A: It is recommended to replace or reapply the tape within its 12-month shelf life to guarantee the retention of its insulating and adhesive properties.Q: Where is Polyimide Film Tape manufactured and supplied?

A: This product is manufactured and exported by established companies in India, and is available through various reputable suppliers for both domestic and international markets.Q: What makes Polyimide Film Tape a strong insulator?

A: Its high CaO content (minimum 90%) and robust polyimide material provide superior thermal and electrical insulation, even at elevated temperatures.Q: What is the benefit of the tapes high melting point?

A: The melting point of up to 1500C ensures that the tape maintains its structural integrity and insulative performance, even under extreme heat conditions often encountered in electronics and industrial processing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese