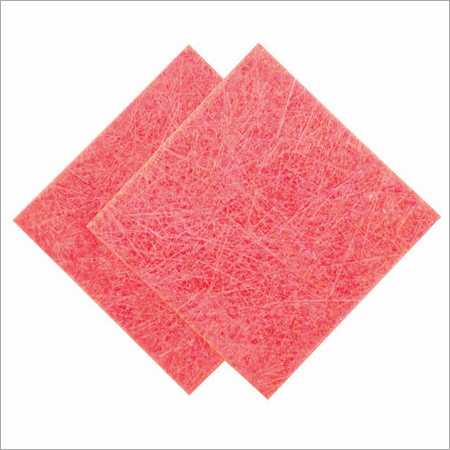

Rigid Glass Mat

Product Details:

- CaO Content (%) 90% min

- Melting Point 1250C and 1500C

- Oil Absorption 0.5%

- Types of Mica Insulator

- Shape Block

- Application Insulator

- Click to View more

X

Rigid Glass Mat Price And Quantity

- 200 Set

Rigid Glass Mat Product Specifications

- 90% min

- 1250C and 1500C

- 0.5%

- Block

- Insulator

- Insulator

Rigid Glass Mat Trade Information

- 2000 Set Per Day

- 4 Days

Product Description

Since our establishment in year 1968, we are engaged in offering a wide variety of Rigid Glass Mat. This mat is highly demanded for rotor winding as it has good thermal insulation. Offered mat is processed with the aid of modern processing techniques and using quality assured mica under the strict guidance of our deft professionals. Moreover, our clients can avail this Rigid Glass Mat from us at marginal prices.

Features:

-

Resistant to heat

-

High dielectric properties

-

Highly flexible

-

Light weight

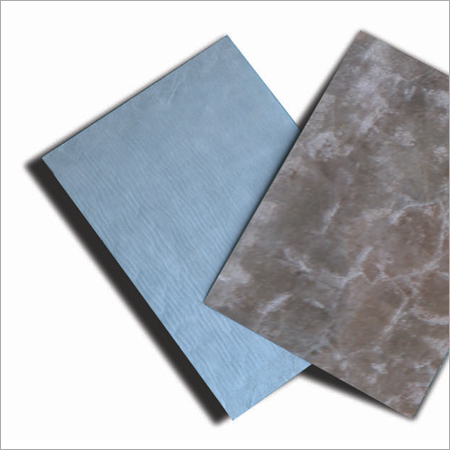

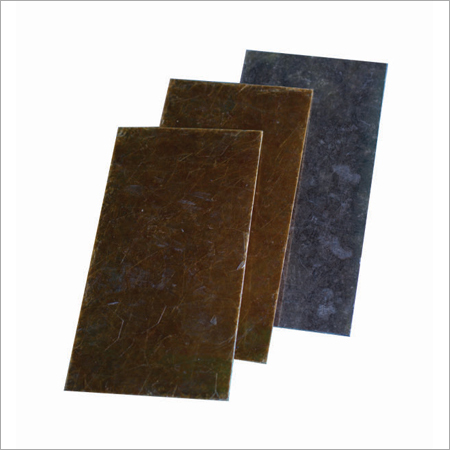

Standard Sheet

- Length : 1000 mm

- Width : 1000 mm

- Thickness : 1 to 5 mm

(Sheets can be sheared to customized sizes)

Packing

Sheets are packed in airtight robust wooden boxes protecting them from dirt, dust and moisture. The packaging also ensures safe transit and storage.

Storage

24 months at 25C

Product Data

| Nominal Thickness in mm | 10.3 | 1.50.3 | 20.3 | 2.50.3 | 30.3 | 40.4 | 50.5 |

| Total Substance g/m210% | 950 | 1425 | 2000 | 2375 | 3000 | 4100 | 4750 |

| Binder Content % | 12-17 | ||||||

| Pressure Resistance Parallel to Layers | 200 N/mm2 min. | ||||||

Advanced Thermal Insulation Solution

Rigid Glass Mats with a high CaO content and minimal oil absorption are engineered to deliver outstanding insulation performance. With melting points reaching up to 1500C, these mats remain stable and efficient even under extreme conditions. Their block shape and consistent composition make them particularly valuable for electrical and industrial insulation applications, helping businesses maintain operational safety and energy efficiency.

Reliable Product for the Indian Market

Crafted as per industry standards, these glass mats serve various manufacturers, exporters, and suppliers across India. Their application as insulators ensures dependable performance in a wide array of environments, from electrical assemblies to high-temperature industrial settings. The trust combines quality materials with a process focus, supporting technological advancement and compliance in the insulation sector.

FAQs of Rigid Glass Mat:

Q: How is the rigid glass mat utilized in industrial insulation applications?

A: The rigid glass mat is primarily used as an insulator in industrial environments, where its high melting point and stability under heat provide reliable protection. Its block shape allows for easy installation in electrical assemblies and equipment requiring high thermal resistance.Q: What makes the CaO content significant in this glass mat product?

A: A CaO content of at least 90% enhances the mats thermal stability and durability, ensuring stable performance under demanding temperature conditions. This high calcium oxide composition contributes to the products effectiveness as an insulator.Q: When should you select a rigid glass mat with a higher melting point?

A: You should choose a glass mat with a melting point of 1500C for environments exposed to extremely high temperatures, such as foundries or high-performance electrical equipment, to ensure sustained insulation and safety.Q: Where are these rigid glass mats manufactured and supplied?

A: These rigid glass mats are produced and supplied in India, catering to manufacturers, exporters, and suppliers requiring robust insulation materials for local and international markets.Q: What is the process for integrating these glass mats into insulation systems?

A: The process involves cutting the block-shaped glass mat to fit specific dimensions and installing it in areas requiring insulation. Its rigidity allows for simple placement and ensures long-lasting insulation without frequent replacements.Q: What are the main advantages of using rigid glass mats with minimal oil absorption?

A: The low oil absorption (0.5%) prevents degradation from exposure to oils and chemicals, enhancing the longevity and reliability of insulation performance in challenging industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese