Mica V Ring

Product Details:

- Melting Point 1250C and 1500C

- Oil Absorption 0.5%

- CaO Content (%) 90% min

- Types of Mica Insulator

- Shape Block

- Application Insulator

- Click to View more

X

Mica V Ring Price And Quantity

- 200 Set

Mica V Ring Product Specifications

- 1250C and 1500C

- 90% min

- 0.5%

- Block

- Insulator

- Insulator

Mica V Ring Trade Information

- 2000 Set Per Day

- 4 Days

Product Description

Mica V-Rings

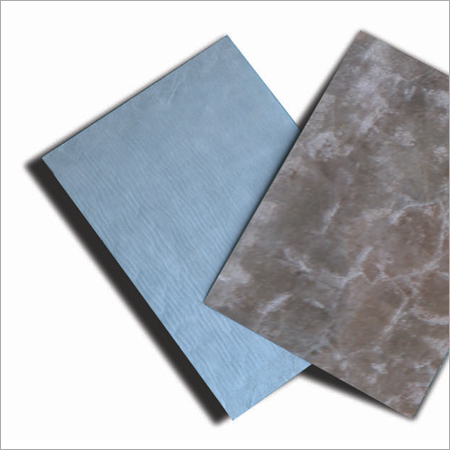

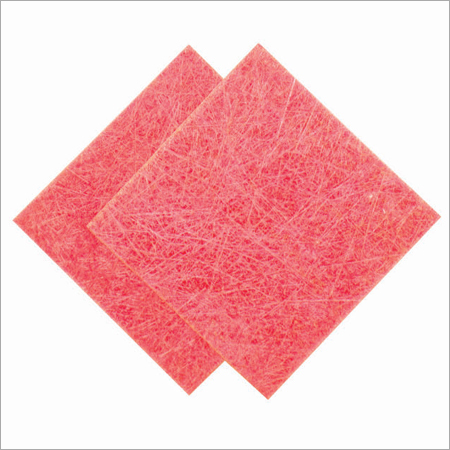

With our consistent efforts, we have carved a special position for manufacturing and exporting a wide array of Micanite. This product range is manufactured by using the high quality materials procured from the reliable vendors of the industry. These products are available in distinguished sizes, shapes and specifications to cater the specific requirements of our highly reputed patrons. Micanite finds extensive punching applications in different domains.

Features:

- Rigid design

- Excellent temperature resistance

- Optimum durability

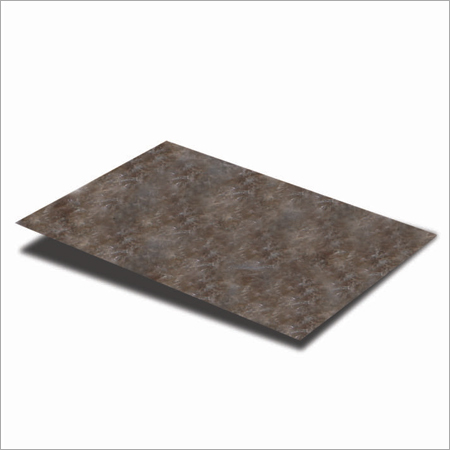

Ruby Micaf V-Rings are made using alkyd vinyl bonded mica splitting-based sheets.The flexible-sheet cut-pieces are molded and formed to a V-Ring shape using heavy cast-iron molds. These molds are subjected to high heat and pressure for a final curing-cycle, yielding a rigid V-Ring. They are ground to a final finish with precise thickness and surface-finish.

These V-Rings are highly-customizable and therefore can be molded to desired shapes and sizes.

Exceptional Thermal Insulation Performance

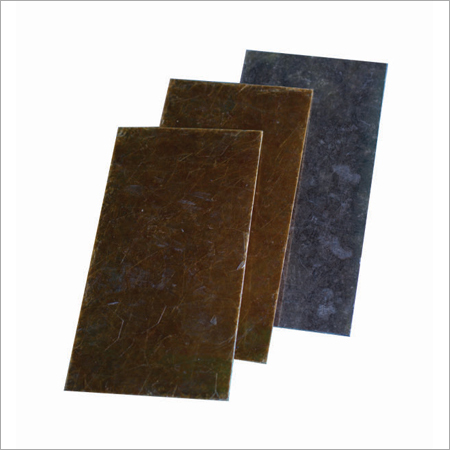

Designed to withstand temperatures up to 1500C, the Mica V Ring delivers outstanding insulation for high-temperature industries. Its minimal oil absorption and superb heat resistance make it suitable for demanding thermal environments, substantially reducing the risk of breakdown.

Premium Material Standards and Composition

With a minimum CaO content of 90%, the Mica V Ring meets rigorous industrial standards. Its robust block shape ensures easy integration into a wide range of electrical and thermal insulation systems, supporting enhanced longevity and operational effectiveness.

FAQs of Mica V Ring:

Q: How is the Mica V Ring utilized in insulation applications?

A: The Mica V Ring is employed as an insulator in systems exposed to high temperatures, acting as a barrier to prevent heat transfer and electrical conduction, making it ideal for furnaces, kilns, and heated machinery.Q: What makes the Mica V Ring suitable for high-temperature environments?

A: Its high melting points of 1250C and 1500C, along with minimal oil absorption and a high CaO content, ensure stable insulation performance in extreme thermal conditions.Q: When should I consider using a Mica V Ring over other types of insulators?

A: You should opt for a Mica V Ring when your system operates in environments with intense heat and requires both superior thermal and electrical insulation.Q: Where can these Mica V Rings be sourced from?

A: These rings are available from specialized exporters, manufacturers, and suppliers in India, catering to both local and global industrial requirements.Q: What is the process behind manufacturing Mica V Rings?

A: Mica V Rings are produced by expertly shaping block-form mica into rings, ensuring high purity CaO levels and stringent quality controls for consistent insulation properties.Q: What are the benefits of choosing a Mica V Ring as an insulator?

A: By using Mica V Rings, industries benefit from enhanced durability, excellent thermal management, low oil absorption, and reliable performance in challenging operational settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese