Glass Mica Splitting Glass Sheet

360 INR/Kilograms

Product Details:

- K2O Content (%) 6-8%

- SiO2 Content (%) 40-55%

- Melting Point Around 1300C 1400C

- CaO Content (%) 13%

- Fe2O3 (%) 12% (for high-purity grades)

- Al2O3 Content (%) 30-35%

- Particle Size 60100 microns

- Click to View more

X

Glass Mica Splitting Glass Sheet Price And Quantity

- 100 Kilograms

- 360 INR/Kilograms

Glass Mica Splitting Glass Sheet Product Specifications

- 12% (for high-purity grades)

- 30-35%

- Insulation Sheet

- 13%

- 60100 microns

- Yes

- 6-8%

- 40-55%

- 68% (common for phlogopite mica, used in high-temperature applications)

- Around 1300C 1400C

Glass Mica Splitting Glass Sheet Trade Information

- 2000 Kilograms Per Day

- 4 Days

Product Description

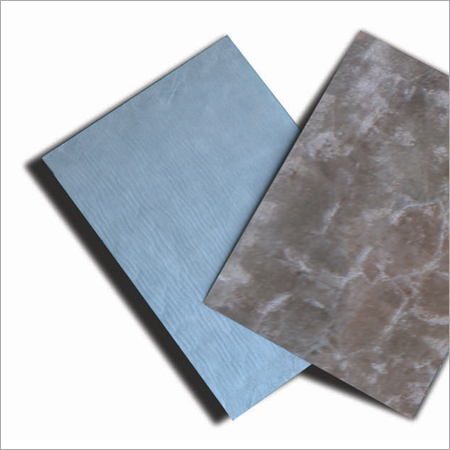

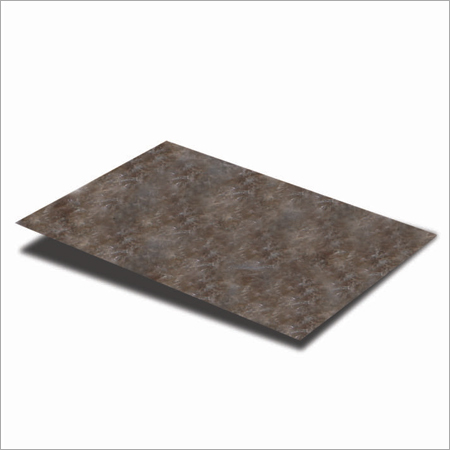

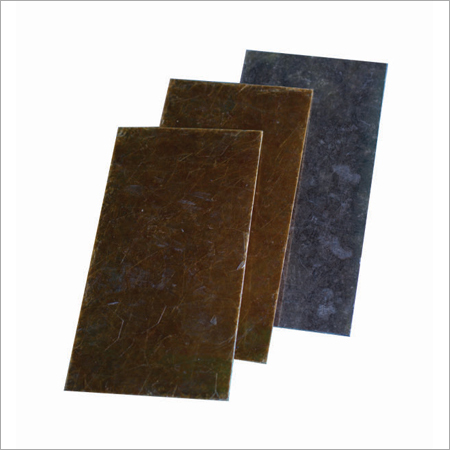

Glass Mica Splitting Glass Sheet

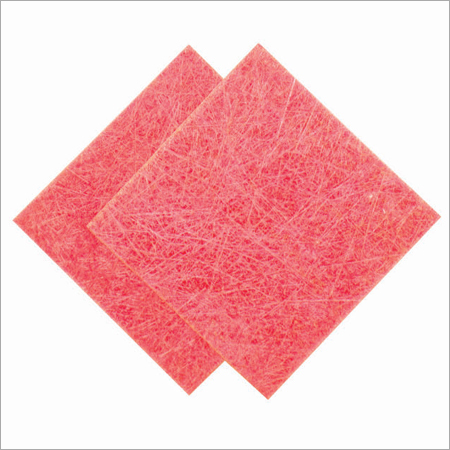

Ruby Mica Glass Micanite Glass Sheet is made by depositing highlyflexible thin films of highquality muscovite mica splittings on top of each other till the required thickness is attained To increase thermalconductivity and improve materialhandling the sheets are backed with glass cloth on both sides High thermalgrade silicone resin is used as a binding agent

Application

Class H ground insulation in HT motors generators coil insulation of heavy lifting electromagnets working in high heat environments

Availability

Standard Sheet

Length 1000 mm

Width 1000 mm

Thickness 01 to2 mm

Sheets can be sheared to customized sizes

Packing

Sheets are packed in airtight robust wooden boxes protecting them from dirt dust and moisture The packaging also ensures safe transit and storage

Storage

12 months at 20C

Product Data

Properties

Test Method

Unit

Value

Nominal Thickness

IEC 603712

mm

0152

Mica Splitting

IEC 603712

754

Glass Content

IEC 603712

102

Volatile Contents

IEC 603712

1

Resin Content

IEC 603712

152

Tensile Strength

IEC 603712

Ncm

400

Dielectric Strength

IEC 602431

KVmm

20

Density

IEC 603712

gcm3

22

Flexibility

Good

Premium High-Temperature Insulation Solution

Our Glass Mica Splitting Glass Sheet is tailored for industries that require exceptional heat and electrical resistance. Thanks to its unique chemical formulation, including high-purity mica, it stands up to extreme environments frequently encountered in metallurgy, electronics, and furnace construction. This ensures reliable performance even under intense thermal or electrical loads.

Quality Materials for Enhanced Performance

Sourced with stringent quality standards, each sheet incorporates an optimal ratio of magnesium, calcium, aluminum, silicon, iron, and potassium oxides. These elements work together to boost the materials thermal stability and dielectric properties, supporting efficient operation in high-stress settings while resisting degradation over time.

FAQs of Glass Mica Splitting Glass Sheet:

Q: How is the Glass Mica Splitting Glass Sheet manufactured?

A: The sheet is made by splitting and laminating phlogopite mica flakes, then combining them with specialized binders and subjected to precise thermal processing. This process ensures consistent chemical composition and robust heat resistance across every sheet.Q: What applications benefit most from this mica glass sheet?

A: This product is ideal for use in sectors requiring insulation against exceptional heat, such as furnace linings, foundry casting, electrical insulation in power devices, and high-temperature gaskets or spacers in metallurgical and electronic industries.Q: Where can the Glass Mica Splitting Glass Sheets be sourced?

A: Our sheets are manufactured, supplied, and exported directly from India. We serve global clients, ensuring fast and reliable delivery to industrial hubs worldwide.Q: When should one choose phlogopite mica type sheets?

A: Phlogopite mica sheets are preferred when applications demand high thermal resistance, superior dielectric properties, and endurance in aggressive operating environments up to 1500C.Q: What advantages do these sheets provide over standard insulation materials?

A: Compared to ordinary insulation materials, these mica glass sheets offer greatly enhanced thermal stability, non-flammability, chemical durability, and excellent electrical insulation, resulting in longer component life and improved equipment safety.Q: How does the chemical composition benefit its use in industry?

A: The tailored contents of MgO, Al2O3, SiO2, K2O, along with low CaO and Fe2O3, synergistically provide a balance of flexibility, heat endurance, and electrical resistance, optimizing the mica sheet for versatile commercial and industrial use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese