Hot Molding Mica Splitting Sheet

Product Details:

- CaO Content (%) 90% min

- Oil Absorption 0.5%

- Melting Point 1250C and 1500C

- Types of Mica Insulator

- Shape Block

- Application Insulator

- Click to View more

X

Hot Molding Mica Splitting Sheet Price And Quantity

- 200 Set

Hot Molding Mica Splitting Sheet Product Specifications

- 1250C and 1500C

- 90% min

- Block

- Insulator

- 0.5%

- Insulator

Hot Molding Mica Splitting Sheet Trade Information

- 2000 Set Per Day

- 4 Days

Product Description

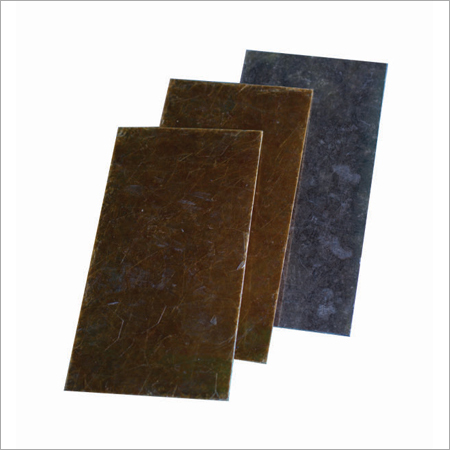

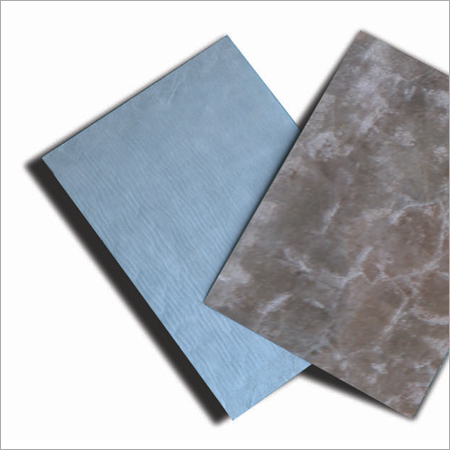

Hot Molding Mica Splitting Sheet

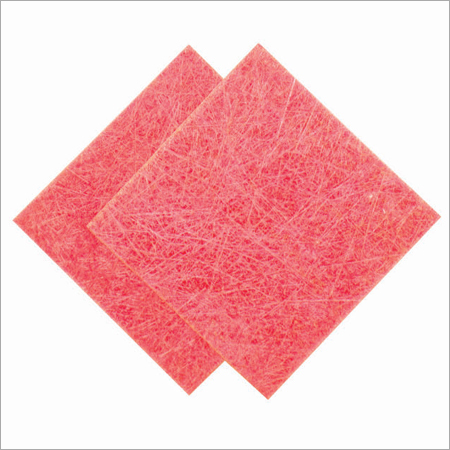

Ruby Mica Hot Molding Micanite Sheet is made by depositing highly-flexible, thin films of high-quality muscovite mica splittings on top of each other till the required thickness is attained.

Currently, hot molding micanite sheet is available with two choices of binding agent. Alkyd resin-bound sheets stay flexible at room-temperature and is cured completely at 180C. Whereas, shellac resin-bonded sheets stay rigid at room-temperature and have to be preheated to gain flexibility before curing it completely at 150C to form a rigid and robust insulation.

Application

Armature coil ground-insulation, armature slots, windings and coil insulation, end-winding turn insulation, bracing rings and V-Ring manufacturing.

Availability

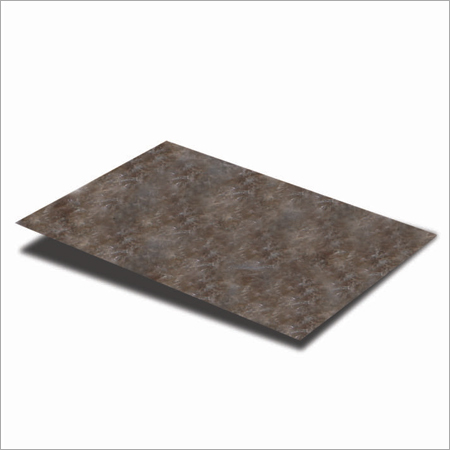

Standard Sheet

- Length : 1000 mm

- Width : 1000 mm

- Thickness : 0.1 to 1 mm

(Sheets can be sheared to customized sizes)

Packing

Sheets are packed in airtight robust wooden boxes protecting them from dirt, dust and moisture. The packaging also ensures safe transit and storage.

Storage

10 months at < 20C

Product Data Sheet

| Properties | Test Method | Unit | Value |

| Thickness Tolerance | IEC 60371-2 | mm | 0.15 |

| Mica Content | IEC 60371-2 | % | 827 |

| Resin Content | IEC 60371-2 | % | 183 |

| Breakdown Voltage | IEC 60243-1 | Kv/mm | 18 |

| Winding Property | - | - | Good |

Exceptional Thermal Endurance

These mica splitting sheets are engineered to withstand extreme temperatures with melting points at 1250C and 1500C. This feature enables them to function effectively under intense heat conditions, ensuring consistent insulation and reducing the risk of thermal breakdown in critical applications.

Versatile Applications in Industry

Used predominantly as insulators, these mica sheets are indispensable for manufacturers and exporters dealing with heavy-duty electrical and thermal insulation needs. Their robustness and low oil absorption capacity make them suitable for a multitude of applications across various industries where reliability and endurance are vital.

FAQs of Hot Molding Mica Splitting Sheet:

Q: How are Hot Molding Mica Splitting Sheets typically used in industrial applications?

A: These sheets are mainly used as insulators in electrical and electronic equipment, providing reliable thermal and electrical resistance for components exposed to high temperatures and voltage.Q: What benefits do mica sheets with 90% minimum CaO content provide?

A: With at least 90% CaO content, these mica sheets offer enhanced heat resistance and outstanding chemical stability, making them suitable for high-performance insulation in harsh environments.Q: Where are these mica splitting sheets commonly manufactured and exported from?

A: These mica sheets are produced and exported primarily from India, which is renowned for its expertise in mica-based insulating products.Q: What is the process for making Hot Molding Mica Splitting Sheets?

A: The manufacturing process involves splitting natural mica blocks, followed by hot molding with high CaO content to form sturdy, heat-resistant sheets or blocks.Q: When should you consider using these mica sheets as an insulator?

A: These sheets should be considered whenever there is a requirement for high thermal endurance, such as in electric furnaces, transformers, and other applications where heat and electrical stability are critical.Q: What is the oil absorption rate of these mica sheets and why is it important?

A: Their oil absorption rate is as low as 0.5%, which is important to maintain insulation effectiveness and prevent material degradation due to oil-based contaminants.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese