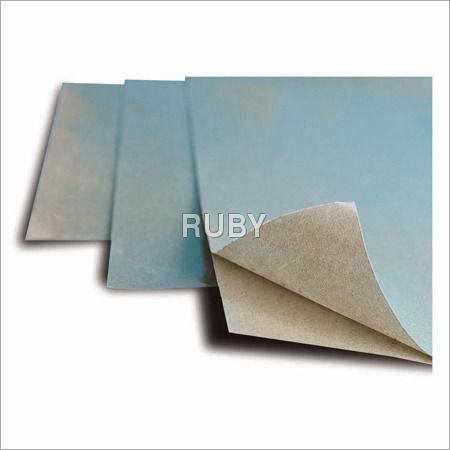

Fiberglass Silicone Bonded Sheet

Product Details:

- Size 9, 13, 16, 19, 25, 32MM

- Product Type Insulation Material

- Material Mica

- Thickness 0.1 mm to 2 mm Micrometers (um)

- Application Sound, Heat Insulation

- Color Multicolor

- Click to View more

X

Fiberglass Silicone Bonded Sheet Price And Quantity

- 100 Sheet

Fiberglass Silicone Bonded Sheet Product Specifications

- Sound, Heat Insulation

- Multicolor

- 9, 13, 16, 19, 25, 32MM

- 0.1 mm to 2 mm Micrometers (um)

- Mica

- Insulation Material

Fiberglass Silicone Bonded Sheet Trade Information

- 2000 Sheet Per Month

- 1 Week

Product Description

Fiberglass Silicone Bonded Sheet

Silicone Bonded Fiber Glass Sheet are made by combining glass cloth with an epoxy/silicone resin as a binder, cured under specific heat and pressure.

It has excellent rigidity, heat-resistance, moisture-resistance and di-electric properties. It is a completely asbestos-free and highly chemical-resistant insulation having low thermal-conductivity. It does not emit smoke or odor upon heating up. Epoxy-based composites can withstand temperature up to 250-300°C, whereas silicone-bonded composites can withstand temperatures up to 350-450°C.

Application

Highly temperature-resistant composites machined-parts for Ferro alloys submerged arc furnace and induction furnace insulation.

Slot packing insulation in HT motors, high-temperature washers in lifting magnets, etc.

Availability

Standard Sheet

| Length | 1000 mm |

| Width | 600/1000/1200 mm |

| Thickness | 0.1 to 50 mm |

(Sheets can be sheared to customized sizes)

Standard Tubes

| Length | 10-1000 mm |

| ID | 6-200 mm |

(Tubes can be rolled to customized sizes)

Machine Composite Parts

Product Data Material

| Fiber Glass Cloth | % | 70 + 5 |

| Epoxy Resin | % | 30 + 5 |

| Fiber Glass Cloth | % | 80 + 5 |

| Silicone Resin | % | 20 + 5 |

Mechanical

| Density | G/cm3 | 1.9 + 0.5 |

| Tensile Strength | MPa | >275 |

| Flexural Strength | MPa | >230 |

| Compressive Strength | MPa | >400 |

Electrical

| Dielectric Strength | KV/mm | >30 |

Thermal

| Operating Temperature | °C | 250-300 (Epoxy) 350-450 (Silicone) |

Other

| Weight Loss | % | <0.5 |

| Water Absorption | % | <0.1 |

Superior Sound and Heat Insulation

Engineered from mica and bonded with silicone, this fiberglass sheet provides excellent heat and sound insulation properties, making it ideal for both commercial and industrial environments. Its multicolor variants allow for flexible application in different aesthetic contexts, while its size and thickness options ensure suitability for diverse requirements.

Versatile Dimensions and Applications

Available in widths ranging from 9mm to 32mm and thicknesses from 0.1 mm up to 2 mm, these sheets cater to various insulation demands. Commonly used in machinery, electrical appliances, and construction, they help enhance energy efficiency and safety in the workplace.

FAQs of Fiberglass Silicone Bonded Sheet:

Q: How is the Fiberglass Silicone Bonded Sheet used in sound and heat insulation applications?

A: This sheet is installed within walls, machinery, or appliances to reduce heat transfer and dampen sound, effectively improving insulation in both industrial and commercial settings.Q: What process is involved in manufacturing the Fiberglass Silicone Bonded Sheet with mica material?

A: The sheets are produced by bonding fiberglass with silicone resin and embedding mica particles. This creates a robust, heat-resistant, and sound-proof insulation material.Q: When should I choose different sizes and thicknesses for the fiberglass sheet?

A: Select the size and thickness based on your specific insulation needs; for heavier insulation, thicker sheets are preferable, while smaller sizes fit compact or detailed installations.Q: Where are these sheets commonly applied?

A: They are widely used in factories, buildings, electrical units, and machinery where effective thermal and acoustic insulation is essential.Q: What are the benefits of using a mica-based fiberglass silicone bonded sheet?

A: Mica enhances the sheets heat resistance and insulation capabilities, while silicone bonding improves durability and flexibility, making it an ideal choice for demanding environments.Q: How does being an exporter and manufacturer in India impact product quality and availability?

A: As an Indian exporter and manufacturer, the product is made to rigorous standards, ensuring quality and easy availability in both local and global markets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese