Fiberglass Epoxy Bonded Sheet

Product Details:

- Size 9, 13, 16, 19, 25, 32MM

- Product Type Insulation Material

- Material Mica

- Thickness 0.1 mm to 2 mm Micrometers (um)

- Application Sound, Heat Insulation

- Color Multicolor

- Click to View more

X

Fiberglass Epoxy Bonded Sheet Price And Quantity

- 100 Sheet

Fiberglass Epoxy Bonded Sheet Product Specifications

- Insulation Material

- Sound, Heat Insulation

- Mica

- 9, 13, 16, 19, 25, 32MM

- Multicolor

- 0.1 mm to 2 mm Micrometers (um)

Fiberglass Epoxy Bonded Sheet Trade Information

- 2000 Sheet Per Month

- 1 Week

Product Description

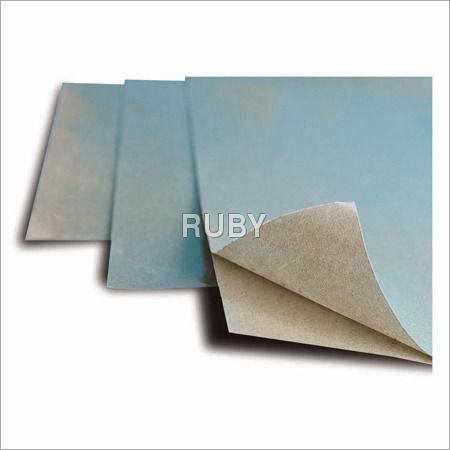

Fiberglass Epoxy Bonded Sheet

Fiberglass Epoxy Bonded Sheet are made by combining glass cloth with an epoxy/silicone resin as a binder, cured under specific heat and pressure.

It has excellent rigidity, heat-resistance, moisture-resistance and di-electric properties. It is a completely asbestos-free and highly chemical-resistant insulation having low thermal-conductivity. It does not emit smoke or odor upon heating up. Epoxy-based composites can withstand temperature up to 250-300C, whereas silicone-bonded composites can withstand temperatures up to 350-450C.

Specification

| Resin Type | Epoxy |

| Thickness | 1 - 75 mm |

| Applicable Temperature | <450 degree celsius |

| Company | RUBY MICA |

Application

Highly temperature-resistant composites machined-parts for Ferro alloys submerged arc furnace and induction furnace insulation.

Slot packing insulation in HT motors, high-temperature washers in lifting magnets, etc.

Availability

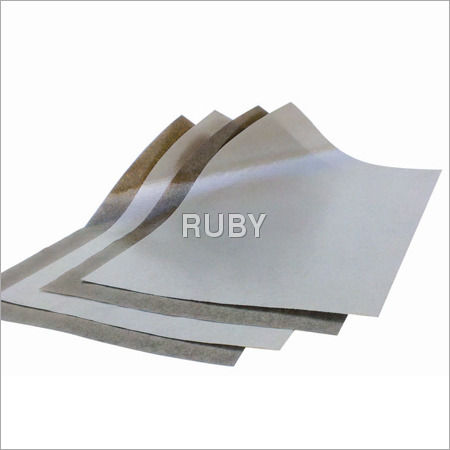

Standard Sheet

| Length | 1000 mm |

| Width | 600/1000/1200 mm |

| Thickness | 0.1 to 50 mm |

(Sheets can be sheared to customized sizes)

Standard Tubes

| Length | 10-1000 mm |

| ID | 6-200 mm |

(Tubes can be rolled to customized sizes)

Machine Composite Parts

Product Data Material

| Fiber Glass Cloth | % | 70 + 5 |

| Epoxy Resin | % | 30 + 5 |

| Fiber Glass Cloth | % | 80 + 5 |

| Silicone Resin | % | 20 + 5 |

Mechanical

| Density | G/cm3 | 1.9 + 0.5 |

| Tensile Strength | MPa | >275 |

| Flexural Strength | MPa | >230 |

| Compressive Strength | MPa | >400 |

Electrical

| Dielectric Strength | KV/mm | >30 |

Thermal

| Operating Temperature | C | 250-300 (Epoxy) 350-450 (Silicone) |

Other

| Weight Loss | % | <0.5 |

| Water Absorption | % | <0.1 |

Superior Insulation Properties

The Fiberglass Epoxy Bonded Sheet utilizes a unique blend of mica and fiberglass, offering both acoustic and thermal insulation. This makes it suitable for environments where minimizing sound transmission and retaining heat are essential, such as in electrical panels, appliances, and construction projects.

Versatile Size and Thickness Options

Available in sizes ranging from 9MM to 32MM and thicknesses from 0.1 mm to 2 mm, our sheets can be tailored to fit distinct project specifications. The multicolor offering also adds flexibility in marking or aesthetic application, making inventory and installation easier for customers.

FAQs of Fiberglass Epoxy Bonded Sheet:

Q: How is the Fiberglass Epoxy Bonded Sheet manufactured?

A: The sheet is produced by bonding mica with fiberglass using high-quality epoxy resin. This process involves layering and curing the materials to achieve strong mechanical and insulation properties, with thicknesses from 0.1 mm to 2 mm.Q: What applications can this sheet be used for?

A: It is ideal for sound and heat insulation across a variety of settings, including electrical panels, household appliances, automotive parts, and construction projects that require reliable thermal and acoustic barriers.Q: When should I choose the suitable sheet thickness?

A: Selection of thickness (0.1 mm2 mm) depends on the level of insulation required and the available installation space. Thicker sheets offer enhanced insulation and durability, while thinner sheets are suitable where space is limited.Q: Where can I source Fiberglass Epoxy Bonded Sheets from India?

A: We are a reputable exporter, manufacturer, and supplier based in India. Customers can directly contact us for bulk orders or customization according to their project needs, with reliable shipping and support worldwide.Q: What is the process for ordering custom sizes and colors?

A: Clients can specify their required dimensions among standard sizes (9, 13, 16, 19, 25, 32MM) and select from the multicolor options. Our team collaborates throughout the ordering process to ensure the exact product specification and timely delivery.Q: How do these sheets benefit industrial and commercial applications?

A: Our sheets provide effective heat and sound insulation, mechanical strength, and chemical resistance, making them highly valuable in reducing energy costs, protecting equipment, and ensuring safety in diverse operational environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese