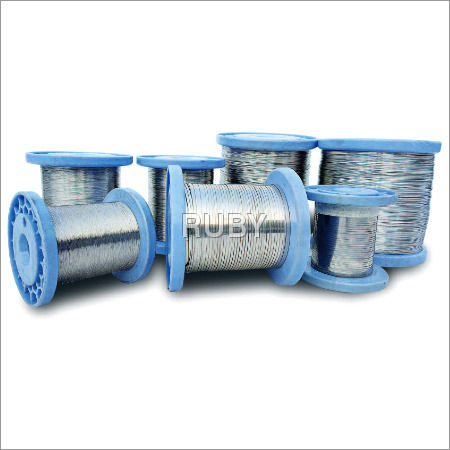

Nickel Chromium Resistive Bunch

Product Details:

- Conductor Material Nickel

- Shape Wire

- Product Type Chromium Wire

- Surface Polished

- Conductor Type Standard

- Insulation Material Other

- Application Heating or Cutting Elements

- Click to View more

X

Nickel Chromium Resistive Bunch Price And Quantity

- 25 Kilograms

Nickel Chromium Resistive Bunch Product Specifications

- Other

- Wire

- Nickel

- Chromium Wire

- Standard

- Polished

- Heating or Cutting Elements

Nickel Chromium Resistive Bunch Trade Information

- 1000 Kilograms Per Day

- 7-14 Days

- Yes

- Free samples are available

- Corrugated box

- All India

Product Description

Nickel Chromium Resistance Wire

With the help of rich industry experience and diligent professionals, we are able to provide Nickel Chromium Resistance Wire. These products are widely demanded as these are used in electrical appliances and machines. Latest tools and machines are used by our qualified professionals to manufacture these products. Our vendors provide us with finest quality nickel chromium used to manufacture these products. The Nickel Chromium Resistance Wire is available in various specifications to relate with the clients needs.

Technical Specifications:

80/20 Nickel Chromium Wire Resistnace Chart

| Size (SWG) | Size (mm) | Resistance Ohm/m | ||

| Min | Mean | Max. | ||

| 20 | 0.914 | 1.578 | 1.66 | 1.744 |

| 21 | 0.813 | 1.995 | 2.100 | 2.205 |

| 22 | 0.711 | 2.608 | 2.745 | 2.883 |

| 23 | 0.610 | 3.543 | 3.730 | 3.916 |

| 24 | 0.559 | 4.219 | 4.441 | 4.663. |

| 25 | 0.508 | 5.109 | 5.378 | 5.647 |

| 26 | 0.457 | 6.313 | 6.645 | 6.977 |

| 27 | 0.417 | 7.582 | 7.981 | 8.380 |

| 28 | 0.376 | 9.326 | 9.817 | 10.307 |

| 29 | 0.345 | 11.077 | 11.660 | 12.243 |

| 30 | 0.315 | 13.287 | 13.987 | 14.686 |

| 31 | 0.295 | 15.150 | 15.947 | 16.745 |

| 32 | 0.274 | 17.561 | 18.486 | 19.410 |

| 33 | 0.354 | 10.521 | 11.075 | 11.628 |

| 34 | 0.234 | 24.078 | 25.346 | 26.613 |

| 35 | 0.213 | 29.060 | 30.590 | 32.119 |

| 36 | 0.193 | 35.395 | 37.258 | 39.121 |

| 37 | 0.172 | 44.566 | 46.912 | 49.257 |

| 38 | 0.152 | 57.065 | 60.069 | 63.072 |

| 39 | 0.132 | 75.668 | 79.651 | 83.633 |

| 40 | 0.122 | 88.581 | 933243 | 97.905 |

| 41 | 0.112 | 101.786 | 110.637 | 118.780 |

| 42 | 0.102 | 122.722 | 133.394 | 143.212 |

| Width (mm) | Thickness (mm) | Resistance Ohm/m | ||

| Min | Mean | Max. | ||

| 1.587 | 0.254 | 2.792 | 2.939 | 3.086 |

| 1.587 | 0.203 | 3.494 | 3.678 | 3.861 |

| 1.587 | 0.152 | 4.666 | 4.912 | 5.157 |

| 1.587 | 0.102 | 6.953 | 7.319 | 7.685 |

| 1.270 | 0.254 | 3.489 | 3.673 | 3.856 |

| 1.270 | 0.203 | 4.366 | 4.596 | 4.825 |

| 1.270 | 0.178 | 4.979 | 5.241 | 5.503 |

| 1.270 | 0.152 | 5.831 | 6.137 | 6.444 |

| 1.270 | 0.102 | 8.689 | 9.146 | 9.603 |

| 1.016 | 0.127 | 8.723 | 9.182 | 9.641 |

| 1.016 | 0.102 | 10.861 | 11.433 | 12.004 |

| 0.794 | 0.254 | 5.581 | 5.875 | 6.168 |

| 0.794 | 0.203 | 6.983 | 7.351 | 7.718 |

| 0.794 | 0.177 | 8.009 | 8.4.0 | 8.852 |

| 0.794 | 0.152 | 9.326 | 9.817 | 10.308 |

| 0.794 | 0.102 | 13.898 | 14.629 | 15.361 |

| 0.794 | 0.098 | 14.392 | 15.150 | 15.907 |

| 0.794 | 0.084 | 16.876 | 17.764 | 18.652 |

| 0.794 | 0.083 | 17.079 | 17.978 | 18.877 |

| 0.635 | 0.113 | 15.686 | 16.511 | 17.337 |

| 0.635 | 0.110 | 16.114 | 16.962 | 17.810 |

Premium Heating and Cutting Solution

Nickel Chromium Resistive Bunch Wire with a polished, standard conductor design is tailored for efficient heating and cutting. Made with nickel for robust conductivity, it guarantees unwavering performance in demanding environments. Exported and supplied globally from India, this wire stands out for its balance of strength, flexibility, and resistance, meeting varied industrial needs with precision.

Trusted Indian Manufacturing Excellence

Sourced from reputable manufacturers, suppliers, and exporters in India, Nickel Chromium wires are produced under stringent quality controls. The expertise in Indian metallurgy ensures each batch is consistent, reliable, and adheres to international standards. The polished finish further enhances electrical characteristics and prolongs usability in various applications.

FAQs of Nickel Chromium Resistive Bunch:

Q: How is Nickel Chromium Resistive Bunch Wire used in heating or cutting elements?

A: This wire is integrated into heating and cutting devices where controlled resistance is essential, allowing efficient energy conversion for heating and precision in cutting operations.Q: What are the benefits of using a polished surface on Nickel Chromium Resistive Bunch Wire?

A: The polished surface minimizes oxidation, enhances conductivity, and extends the wires lifespan in both heating and cutting environments, ensuring cleaner and more consistent performance.Q: When should you choose Nickel Chromium Resistive Bunch Wire with a standard conductor type?

A: The standard conductor type is ideal for applications requiring uniform resistance and reliable performance, especially in commercial and industrial heating or cutting systems.Q: Where is this wire manufactured and supplied from?

A: Nickel Chromium Resistive Bunch Wire is manufactured, exported, and supplied by trusted Indian companies, known for their expertise and adherence to quality standards.Q: What is the process of manufacturing the Nickel Chromium Resistive Bunch Wire?

A: Manufacturers in India use advanced drawing and bunching techniques to combine nickel conductors, applying a polished finish to achieve optimal resistance and surface integrity.Q: How does using nickel as the conductor material benefit heating or cutting applications?

A: Nickels high conductivity and corrosion resistance make it highly suitable for resistive wire, allowing consistent performance under high temperatures and prolonged operational life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese