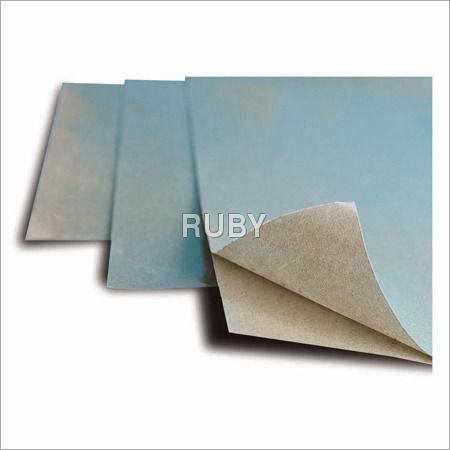

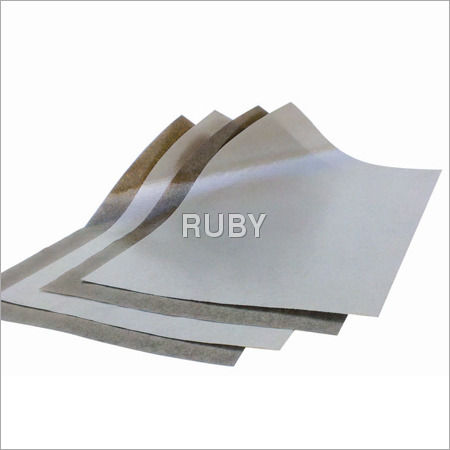

Epoxy Bonded Rigid Mica Laminate

Product Details:

- Size 9, 13, 16, 19, 25, 32MM

- Product Type Insulation Material

- Material Mica

- Thickness 0.1 mm to 2 mm Micrometers (um)

- Application Sound, Heat Insulation

- Color Multicolor

- Click to View more

X

Epoxy Bonded Rigid Mica Laminate Price And Quantity

- 100 Sheet

Epoxy Bonded Rigid Mica Laminate Product Specifications

- Sound, Heat Insulation

- 0.1 mm to 2 mm Micrometers (um)

- Multicolor

- 9, 13, 16, 19, 25, 32MM

- Mica

- Insulation Material

Epoxy Bonded Rigid Mica Laminate Trade Information

- 2000 Sheet Per Month

- 1 Week

Product Description

Epoxy Bonded Rigid Mica Laminate

Ruby Mica Rigid Mica Laminate is made by combining uncalcined muscovite or phlogopite mica-paper with an inorganic silicone-resin binder under specific heat and pressure.

It has excellent rigidity, heat-resistance, moisture-resistance and di-electric properties. It is a completely asbestos- free and highly chemical-resistant insulation having low thermal-conductivity. It does not emit smoke or odor upon heating up. Since the binder plays a critical role in the overall product performance, the best commercially-available resin,with as much as 82% solid silicone content,is imported from Germany for excellent results.

Muscovite mica paper-based material can withstand temperatures up to 600°C whereas, phlogopite mica paper- based material can withstand high temperatures up to 800°C. The product is IEC 60371 -3-3 compliant.

A choice of epoxy resin is also available as a binder. Ruby Mica Epoxy Rigid Mica Laminates have higher rigidity, highly-uniform surface profile and weatherproof properties when fully cured. However, the working temperature is limited to 250oC - 300°C. They are mainly used for commutator-segment insulation.

Application

Heating-element supports, winding-cards and cover-plate insulation in domestic appliances and industrial-heating elements. Its superior chemical-resistance makes it an ideal battery-cell separator. Highly temperature-resistant mica machined parts for complete Ferro alloys submerged arc furnace and induction furnace insulation. Dynamic breaking resistors in railways and plate-insulation in heated presses.

Thermocouples and conductor insulation.

Availability

Standard Sheet

- Length 1000 mm

- Width 600/1000/1 200 mm

- Thickness 0.1 to 75 mm

- (Sheets can be sheared to customized sizes)

Standard Tubes

- Length 10 -1000 mm

- ID 6 - 200 mm

- (Tubes can be rolled to customized sizes)

Superior Insulation for Demanding Environments

Epoxy Bonded Rigid Mica Laminate offers outstanding sound and heat insulation, making it a trusted choice in industries where safety and performance are paramount. Its ability to resist high temperatures, combined with mechanical strength, makes it perfect for use in electrical equipment, furnaces, and protective barriers.

Wide Range of Sizes and Thicknesses

Our mica laminates are available in several standard sizes (9, 13, 16, 19, 25, 32mm) and customizable thickness options from 0.1 mm to 2 mm. This versatility allows you to precisely fit insulation requirements across different projects and applications.

Made in India: Quality and Reliability

Manufactured and exported from India, these mica laminates undergo stringent quality control processes. As a direct supplier and exporter, we guarantee dependable delivery and support, ensuring that you receive products tailored to international standards.

FAQs of Epoxy Bonded Rigid Mica Laminate:

Q: What is Epoxy Bonded Rigid Mica Laminate used for?

A: Epoxy Bonded Rigid Mica Laminate is primarily utilized for sound and heat insulation in industrial and electrical environments, such as switchgear, furnace linings, and high-temperature barriers.Q: How is epoxy bonded mica laminate manufactured?

A: The laminate is produced by layering natural mica sheets and impregnating them with epoxy resin. This composite is then cured under pressure, resulting in a rigid, durable, and non-conductive sheet product.Q: When should I consider using mica laminate for insulation?

A: You should opt for mica laminate whenever you need excellent thermal and acoustic insulation, particularly in applications exposed to high heat or requiring electrical safety, offering both protection and longevity.Q: Where can these mica laminates be sourced?

A: These laminates are available directly from manufacturers, exporters, and suppliers in India, such as ourselves, who offer global shipping and custom solutions for bulk requirements.Q: What are the benefits of using mica laminate over other materials?

A: The main advantages are its superior resistance to heat, electrical insulation, sound dampening properties, and mechanical strength, making it more reliable than most conventional insulating materials.Q: How do I select the right size and thickness for my application?

A: Select the size and thickness according to your insulation needs. Our range (932mm in size and 0.12mm thickness) provides flexibility for most requirements, and you can always consult our technical team for guidance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese