Mica Based Heating Elements

Product Details:

X

Mica Based Heating Elements Price And Quantity

- 1 Piece

Mica Based Heating Elements Trade Information

- 1 Piece Per Week

- 1 Days

Product Description

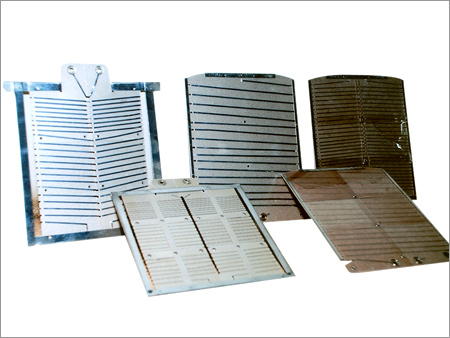

Mica Based Heating Elements

To suit the variegated requirements of our customers, we offer Mica Based Heating Elements. These products are mainly used to insulate heat from electrical appliances like, rice cookers, heaters, iron and many more. Our qualified professionals manufacture these products making use of modern tools and machinery. Our vendors offer us with superior quality mica, which are strong and offer best heat insulation. We offer these Mica Based Heating Elements in various sizes and specifications for our valued clients.

Mica Heating Elements in all Designs, Wattage, and Voltage for use in Ironing Appliances, Toasters, Kettles, Rice Cookers, Hair Dryers, etc.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese